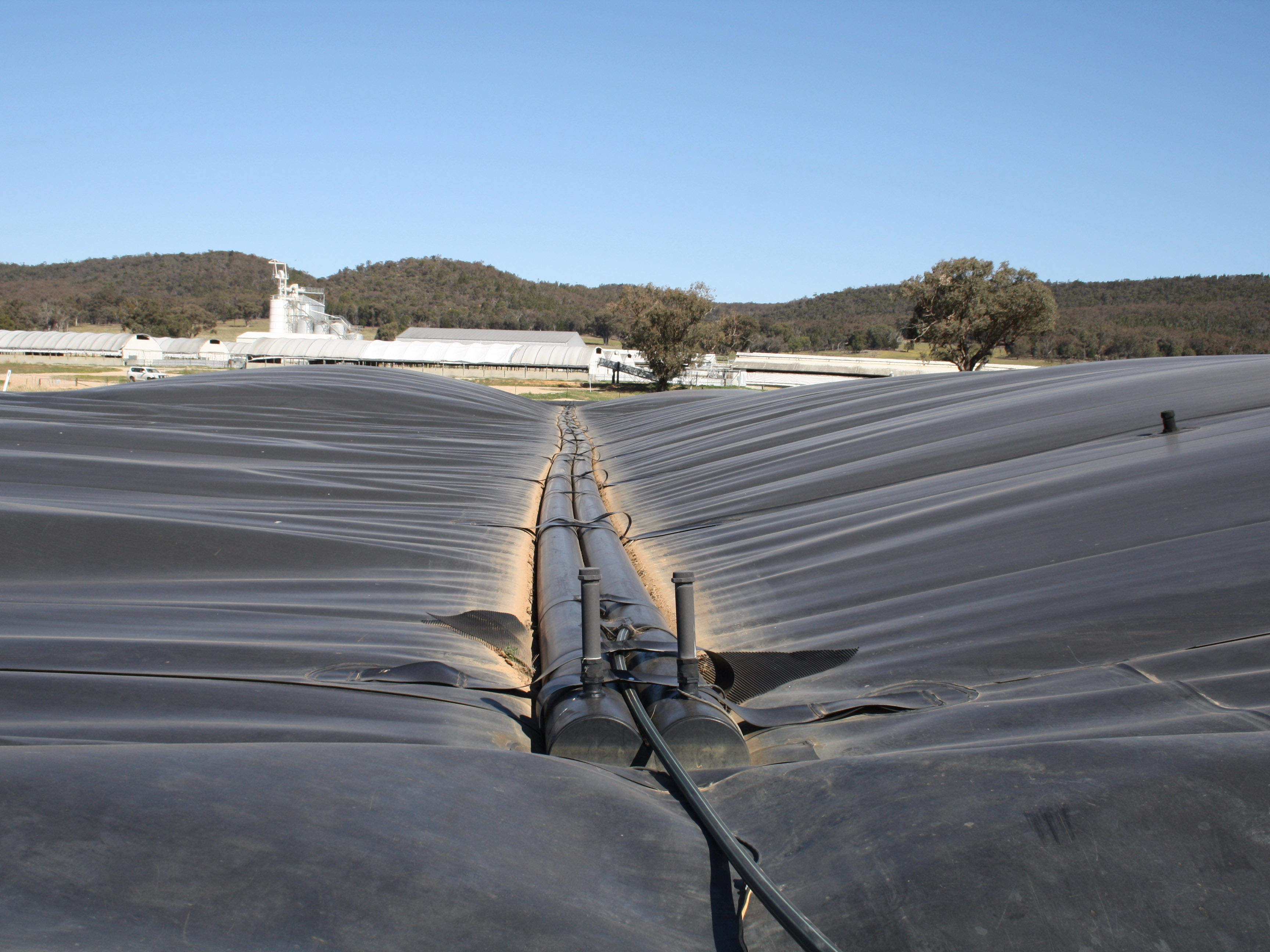

The pork industry is proactively working to reduce its impact on the environment. By maintaining natural resources, using renewable energy sources, we are farming sustainably and can ensure a competitive future for our industry.

Sustainability

Management